Development of a robust and versatile graphene-based conductive ink as a substitute for metal-based conductive ink products for printed electronics, wearable technology and flexible electronics applications.

Overview

Mi-GraphPrInk is a proprietary graphene-based conductive ink technology developed based on the need of the industry as a substitute for metal-based conductive ink predominantly used in the Electrical & Electronics (E&E) industry at present.

The developed graphene-based conductive ink will also enable the development of next-generation printed

electronics, wearable technology and flexible electronics applications.

Features

Mi-GraphPrInk comprises the following features:

• High Conductivity

A graphene-based conductive liquid with conductivity comparable to metal-based conductive liquid.

• Inkjet Printable

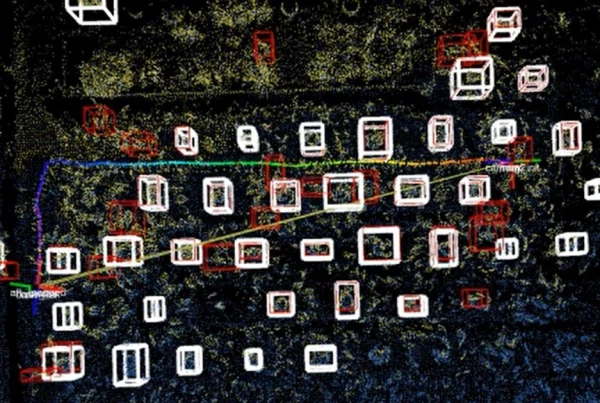

Proven jettability on inkjet printing process (based on Dimatix DMP series of cartridge) with viscosity of below 15cP.

• Monolayer

Monolayer thickness of graphene-based elements for ease of jetting and reduction in print head clogging.

• Customisable

Can be modified, tuned and tailored to required needs and specifications.

Technology Benefits

The main impacts of Mi-GraphPrInk are:

- Low Cost

A reduction in 80% of metal-based elements without compromising the conductivity of the developed ink

products. High jettability of the ink ensures that less volume is required to develop conductive film wit similar sheet resistance. Quality of the hybridised-graphene used is controlled at a consistent and uniform manner across the solvent.

- Environmental Sustainability

Graphene is a carbon-based nanomaterial which ensures environmental sustainability for bulk usage particularly

in the electrical and electronics industry.

- Enabling Technology

Functionalisation of base graphene conductive ink to form new types of conductive ink products can be achieved through process add-ons and the use of proprietary chemical synthesis processes leading to the development of nanosensing materials, conductive interconnects, coatings, flexible electronic platforms and others.