Graphene Conductive Ink

Since 2016, MIMOS has been studying the characteristics of Graphene to explore the many benefits it can provide Malaysia’s E&E Industry. It is now ready to revolutionise Malaysia’s semiconductor electronics and wearables technology, and boost its manufacturing industry, making Malaysia a global industry player. It has wide-ranging applications from industrial engineering, intricate electrical and electronics and consumer-based products, and wearables to the Internet of Things (IoT).

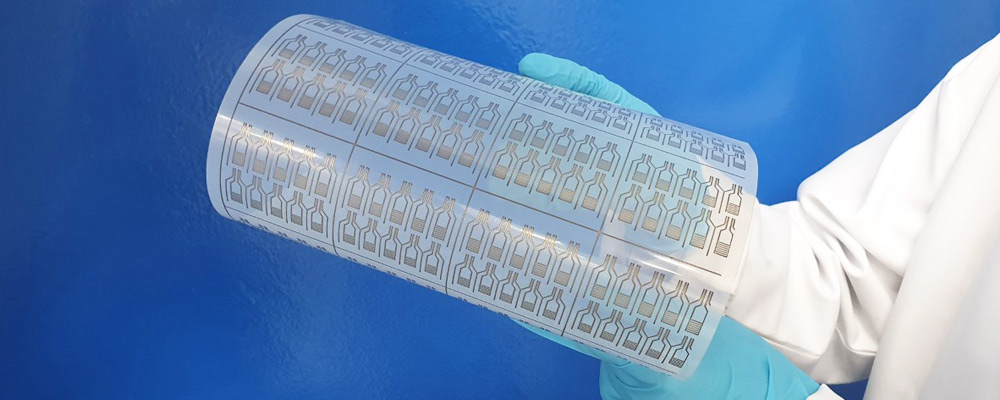

One of MIMOS’ focus areas of research is Graphene-conductive ink, which can be used to create printed materials that conduct heat and electricity. It has many advantages over other metal-based conductive inks, especially those that rely on silver and copper, making it a highly sought-after product with many interesting potential applications.

One of MIMOS’ focus areas of research is Graphene-conductive ink, which can be used to create printed materials that conduct heat and electricity. It has many advantages over other metal-based conductive inks, especially those that rely on silver and copper, making it a highly sought-after product with many interesting potential applications.

In addition to being exceptionally strong, transparent and non-toxic, it is also a more environmentally-friendly alternative to silver-based inks. Silver cannot be recycled, indicating that every single-use electronic product must be disposed of. Graphene, on the other hand, can be recycled and used to produce more eco-friendly printed electronics.

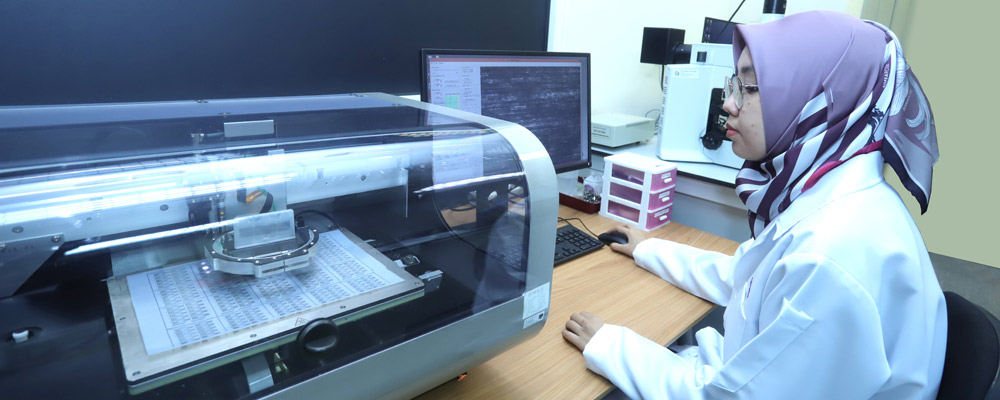

This technology also allowed an alternative fabrication technology leveraging the inkjet printing process, which requires fewer materials usage, faster, simpler setup, and less materials wastage. E&E industry companies manufacturing flexible substrates, advanced packaging, electronic packages, printed electronics, and wearables could take advantage of this technology and save time and reduce labour and materials costs. Consumers, healthcare and lifestyle practitioners could also reap the benefits of Graphene technology, such as applying it in the packaging of electronics, conductive clothing, disposable sensors and 3D printing. Graphene is the future of a sustainable E&E Industry.

This technology also allowed an alternative fabrication technology leveraging the inkjet printing process, which requires fewer materials usage, faster, simpler setup, and less materials wastage. E&E industry companies manufacturing flexible substrates, advanced packaging, electronic packages, printed electronics, and wearables could take advantage of this technology and save time and reduce labour and materials costs. Consumers, healthcare and lifestyle practitioners could also reap the benefits of Graphene technology, such as applying it in the packaging of electronics, conductive clothing, disposable sensors and 3D printing. Graphene is the future of a sustainable E&E Industry.