Analysing crude palm oil | Spectroscopy, a study of the absorption and emission of light and other radiation by matter, is one of the techniques used by MIMOS’ Photonics Technology Lab in its research and development (R&D) activities, with medical electronic devices as one of the application focus areas.

MIMOS has developed several non-invasive and non-intrusive medical technology platforms using ultraviolet (UV), visible, and near-infrared (NIR) spectroscopy methods, such as blood glucose monitoring, Alzheimer’s scanning, and dental caries screening.

Last year, MIMOS’ UV Spectroscopy project on the detection of dental caries earned two awards, signifying the company’s technological prowess.

Spectroscopy Approaches in the Agriculture

Besides medical electronic devices, MIMOS has also employed spectroscopic approaches in the agriculture sector by developing an inline prediction tool using NIR optical fingerprint focusing on crude palm oil (CPO) quality screening.

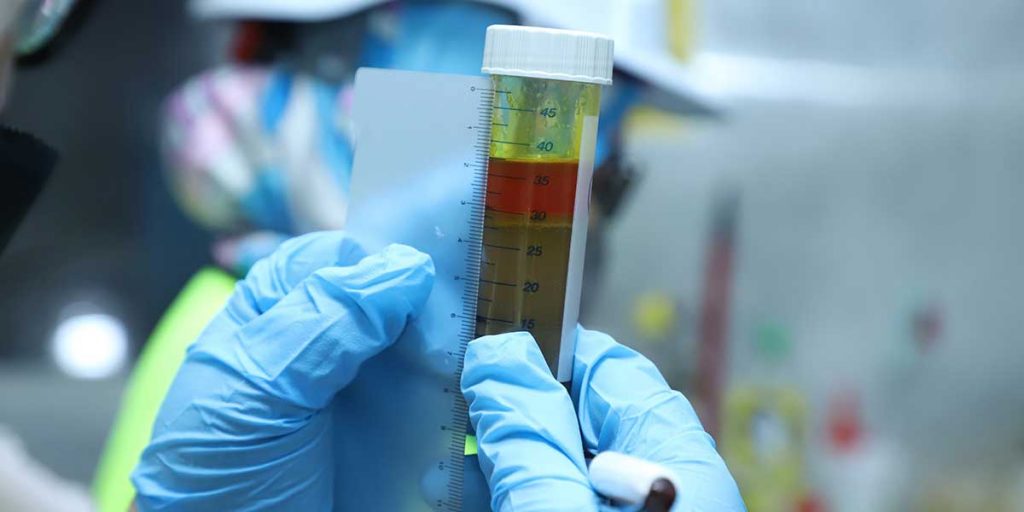

The quality control of CPO necessitates constant monitoring and testing. One of the most common laboratory procedures to monitor and measure CPO quality is titration. Not only titration is laborious, but it is also a risky process since it involves hazardous chemicals.

The laboratory procedures also expose stakeholders to the risk of storing palm oil in the wrong quality or grade storage tank, resulting in massive losses.

To address this issue, MIMOS has developed a rapid, non-destructive, non-chemical, and real-time NIR spectroscopy analytical measuring system for CPO quality screening, making it an innovative and cost-effective solution to evaluate and monitor CPO quality during the milling process.

The analyzer system features a built-in chemometric analysis model to measure and perform quality monitoring by quantification of Free Fatty Acid (FFA), water content, and oil content.

The system also incorporates artificial intelligence, optoelectronics, Internet of Things (IoT), big data analytics as well as communication and cloud infrastructure.

The proof-of-concept has been deployed at the Sime Darby mill and will be expanded to other mill operations.